California Heart

Founded by artist and visionary Brittany Groshong, Valley Rose was created to celebrate art through jewelry using ethical materials that leave this world a better place. Named after Sonoma Valley California, and Brittany's lifelong inspiration of roses, Valley Rose was the perfect appellation that embodied the romance and wild spirit of our collection. Quickly our jewelry gained recognition for our use of rare gemstones and creative silhouettes, and continues to be sought after for its masterful craftsmanship and unique storytelling.

Mediterranean Soul

Valley Rose's home base is now located in Catalunya, the heart of the Spanish Mediterranean. Also known as the birthplace of modern art, Brittany harnesses the rich artistic heritage of Northern Spain and infuses it into her jewelry collection. Surrounded by the natural beauty of Costa Brava Brittany's jewelry continues to focus on pushing creative boundaries while still maintaining at its heart the love of craft and creating heirlooms that transcend generations.

Nothing is art if it does not come from nature.

Antoni Gaudí

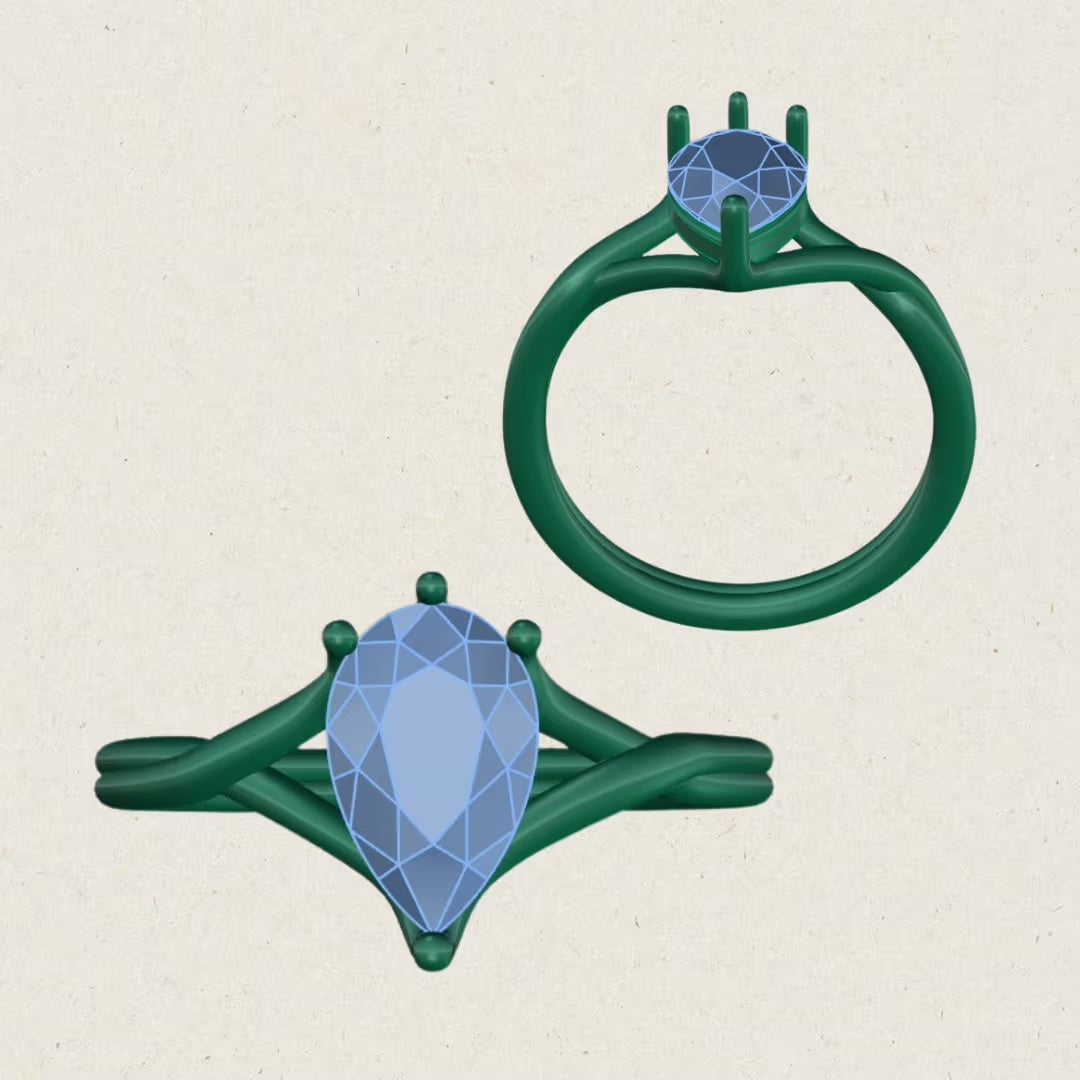

Designed by Artist and Visionary: Brittany Groshong

Born with a paintbrush in her hand, Brittany is the epitome of a multi-disciplinary artist. Though a classically trained painter, to Brittany any an all art mediums are fair game. For her undergrad she earned a Bachelors of Arts Degree from SFAI. Post university Brittany naturally gravitated towards the beauty industry and came to specialize in creative direction and marketing. After a decade in the beauty industry, Brittany felt the call to develop her own project that would be the perfect marriage between her two worlds: art and commercial storytelling. Then in early 2017, Brittany serendipitously stumbled upon jewelry making. When she picked up her first torch something magically clicked into place and she instantly knew that it was meant to be. Valley Rose has since evolved into a vehicle for Brittany's imagination and creativity while offering a fresh and unique perspective to modern fine jewelry.

Our Sustainability Commitment

We believe jewelry shouldn't cost the earth.

Supporting Mining Communities

By becoming a Fairmined Certified brand we pledge to support artisanal mining communities as we believe this is the future to making the jewelry industry more equitable and eco-friendly. We are also certified by SCS global services to carry 007 Sustainably rated diamonds. By using 3rd party audited materials we can help improve the future of this industry.

Rigorously Vetted from Mine to Market

Every step in our sourcing process in carefully considered. From the miners to the cutters to the stone setters. Before taking on a new vendor we carefully examine their procedures to ensure that everything meets our standards and that people have been treated and paid fairly. We constantly examine our vendors to ensure they continually meet our standards.

Consciously Made Slow Jewelry

Instead of mass made fast jewelry we offer slow jewelry using a eco-friendly on demand production model. This allows us make the exact inventory that is needed and ensures there is waste in our inventory. In addition we carefully design every last detail to make certain that stones are secure and there is no risk of breakage or warping.

The Highest Standard of Craft